Warehouse Design and Layouts

- Home

- Warehouse Design and Layouts

CALL US

+44 (0)1926 430 883

E-MAIL US

[email protected]

SCCG will design a suitable and flexible facility, considering future business growth plans

Establishing and implementing the most suitable and relevant warehouse design from the outset, can have a profound influence on the useful life of the facility, its capacity and productivity, and of course, significant financial benefits.

Modelling a range of options to determine an appropriate design, the Specialist Warehouse and Distribution Design Consultants at The Supply Chain Consulting Group (SCCG) use a well-established methodology to build a picture of what to expect from a warehouse during periods of typical and peak-activity from go-live; whilst simultaneously including specific agreed planning horizons for individual client requirements.

SCCG will design a suitable and flexible facility, considering future business growth plans, to ensure warehouse operations can adapt to changes in volume and product-type. Modelling a range of options to arrive at an appropriate design, our logistics consultants use a well-established methodology to build a picture.

Warehouse and Distribution Centre Design Consultants

Our Warehouse and Distribution Centre Design Consultants have a detailed knowledge and understanding of what is required to operate an efficient Distribution Centre, warehouse and picking/despatch operation.

Our in-house CAD facilities enables our Warehouse and Distribution Centre Consultants to provide clients with bespoke and detailed scale plan view drawings, 3D representations of the plan in full or in part, and an automatically generated complete Bill of Material (BOM) to enable racking and MHE suppliers to provide accurate quotations for supply and installation.

Our Warehouse Design Layout Services

We regularly work with our clients in establishing :

- Building and site size and dimensions

- New build design and re-configuration of existing warehouse, picking and distribution facilities

- Facility sizing and Distribution Centre (DC) capacity assessment

- Optimised facility CAD designs/layout, handling practices and workflows

- Automation and materials handling systems specification, development and implementation

- Warehouse and inventory management techniques to optimise workflow and costs

- Cost to Serve and Pick Rate Modelling to support the optimised layouts and workflows

- Optimised target inventories (holding cost vs. ordering cost vs. service)

- Tactical stock location(s) and picking strategies

- Improved demand forecasting to allow for optimised inventories

- Warehouse Management System (WMS) functional and operational requirements specifications

- Systems and equipment specification, procurement and implementation

- MHE and labour resource models

- Capital and operating budgets

- Advice on New Build site selection, in partnership with your chosen property consultants

- Operating process design and documentation

- Specification and tendering of automation including sortation, automated storage and put away (AS/RS) systems, miniloads and specialised picking systems

- Specification and tendering of equipment including racking, shelving, forklift trucks

- Project management and risk minimisation

- E-commerce logistics centre operational expertise

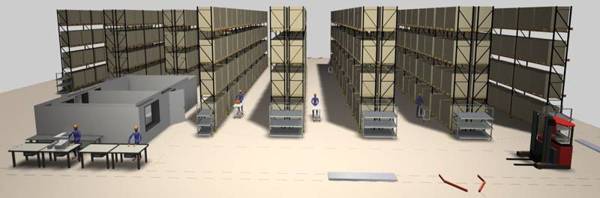

Fig 1: Warehouse, Picking & Packing Area - Plan View and 3D Representation

The CAD software, capable of assisting planning from simple single storey building racking layouts to more complex multi-level facilities with automated handling conveyors, has been proven on client projects by the warehouse and distribution centre design team, all who have had many years’ warehouse and distribution centre operational logistics management experience across a range of industry sectors.

Fig 2: Example of Mezzanine Floor with a conveyor system

The ability to easily change drawings gives their clients a choice of layouts to optimise workflows; enabling them to develop their warehouse processes and standard operating procedures in line with supply chain and logistics strategy requirements

Think the SCCG team are the right fit for your business? Drop us a line today and lets improve your operation efficiency.

Clients Case Studies

Weidmann Case Study

Warehouse Review and WMS selection for a Creative Agency

Warehouse Design Project for Davis and Shirtliff

Warehouse Design and Implementation for a Luxury Retailer

- s&op ·

Wacoal (Formerly Eveden Group) Case Study

Volvo Group Case Study

Triumph Motorcycles Case Study

ToffeIn Case Study

The Supply Chain Consulting Group Supports Zorbas

Examples of Clients We've Helped

Get in Touch

Call us on +44(0) 1926 430 883

Supply chain and Logistics Specialists highly experienced in all aspects of Supply Chain and Logistics Operations, Distribution Network Strategy, Warehousing Operations, e-commerce Logistics and Warehouse and Distribution Centre Design.

Supply Chain

Warehousing

Logistics

Office 26, Pure Offices

Plato Close

Tachbrook Park

Leamington Spa

CV34 6WE

The Future Works

2 Brunel Way

Slough

SL1 1FQ

The Supply Chain Consulting Group Limited

No1 Balloon Street

Manchester

M4 4BE

A supply chain and logistics specialist with knowledge of logistics network planning, warehouse design and material sourcing.

Registered in England and Wales. Company Registration No: 09751027.

Registered office at Innovation House, Molly Millars Close, Wokingham, England, RG41 2RX. UK.