In the final article in this series, we look at the design and operation of inbound and outbound facilities and some important but neglected areas in the warehouse.

We have already covered here how to approach the design and layout of a distribution centre (DC) and here, what to do when deciding on picking equipment and storage. When these decisions have been made, the overall layout design of the facility must be established.

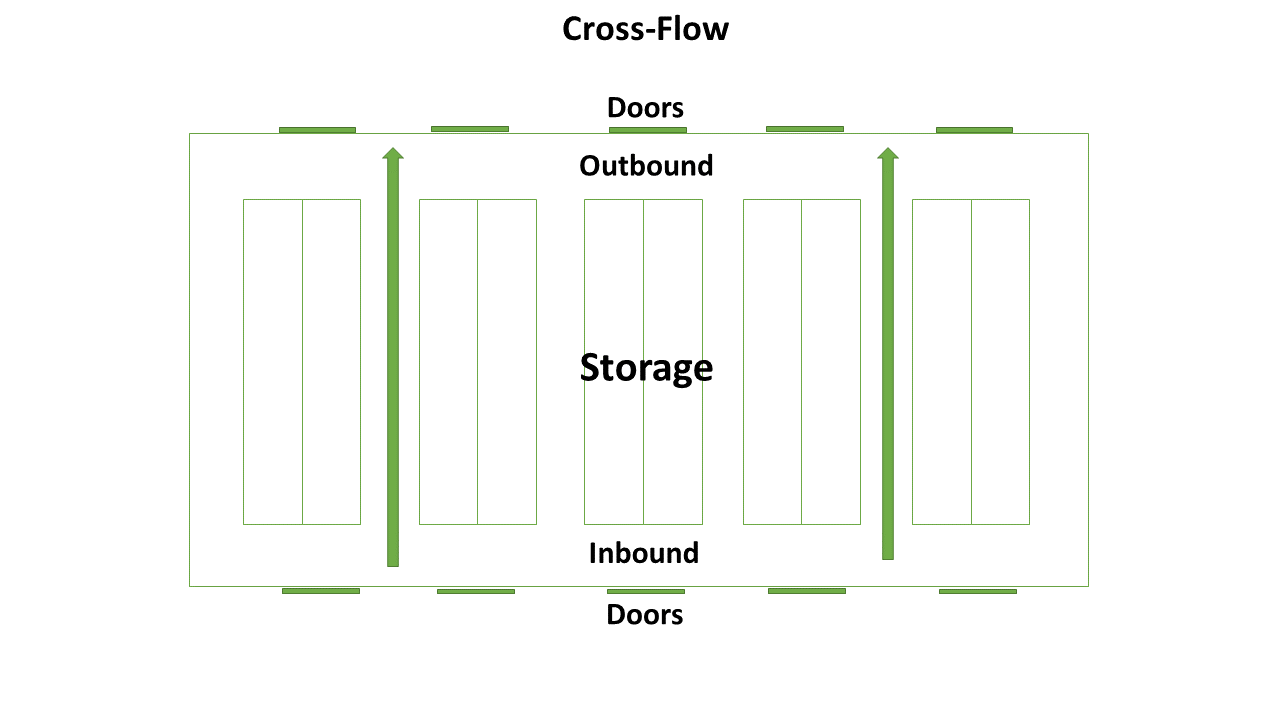

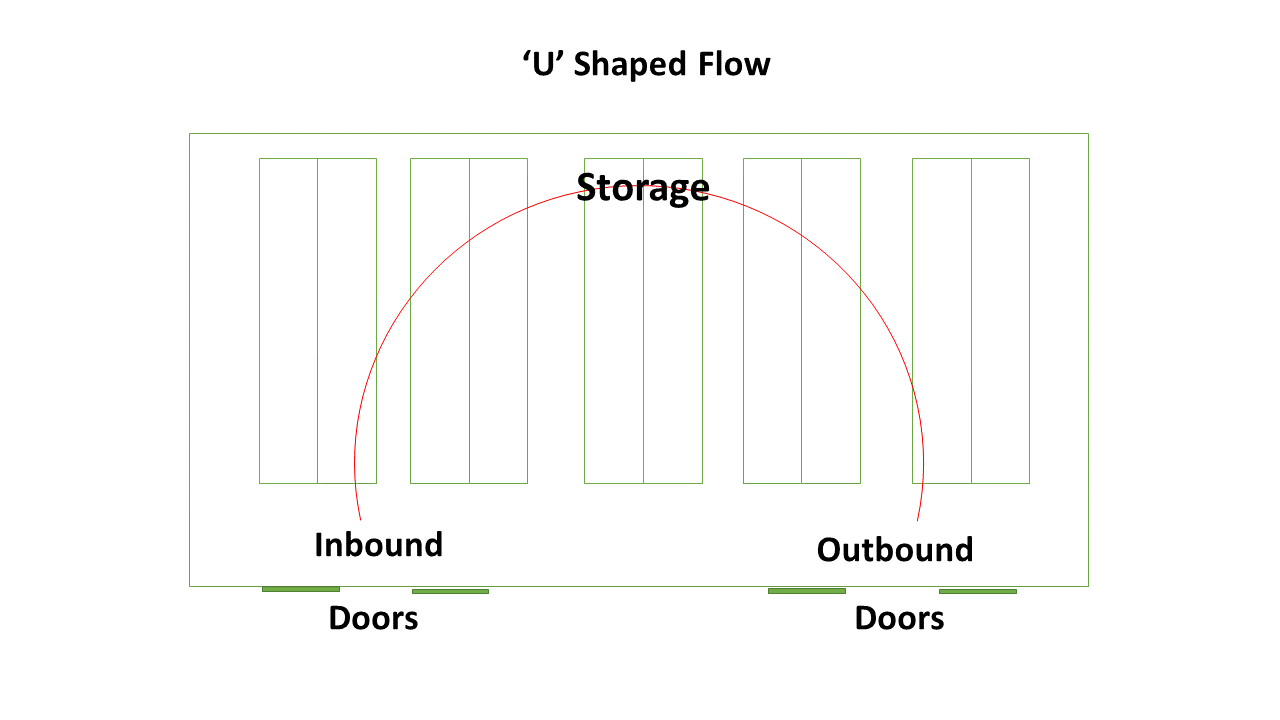

Crossflow or U-shape layout?

The crossflow design is generally suited to very fast-moving environments (e.g. supermarket regional DCs), while warehouses handling general merchandise with several weeks of stock cover would use the U-shaped flow.

The crossflow design means more space is given over to inbound and outbound areas with more doors to facilitate the very high throughput.

In many situations, the U-shaped design works better as it provides more storage capacity and allows sharing of inbound/outbound areas.

Inbound area considerations

Not all inbound shipments have the same handling requirements. Key elements to determining the required space and number of receiving stations or docks that are required depend on

- arrival times of vehicles

- waiting time before unloading

- time taken to unload

- the number of SKUs per delivery – from one to many

- quarantine or quality testing requirements, e.g. pharmaceuticals

- physical handling requirements, e.g. hazardous or fragile items

The inbound flow is also determined by the reliability of your suppliers to deliver in your specified time window and their adherence to pre-defined lead times.

What do you do about handling customer returns? With the increase in e-commerce activity and more goods being returned, this is becoming a design decision. Lack of enough receiving docks can significantly constrain warehousing operations. On arrival and after unloading, goods will often stand on the floor before being put-away. This may be because counting and / or quality checking is required, or because a different type of handling equipment is needed. Inbound areas can quickly be clogged up with goods due to a disconnect between unloading and availability of put-away resources.

The more complex the handling required, the more important it is to have a warehouse management system (WMS) capable of supporting the level of detail required. Software solutions include dock scheduling and staff allocation to optimize the handling of incoming shipments. Security is also an important factor in the design of inbound areas as high-value goods are at risk if not managed tightly.

Outbound area considerations

Dispatch is the final process in the journey of goods from the warehouse to the customer. It is successful only if the right order is sorted and loaded, is dispatched to the right customer, travels through the right mode of transport, and is delivered safely and on time.

Key elements to determining the required space and number of dispatch stations or docks required depend on:

- availability of type and number of vehicles

- waiting time before loading

- time taken to load

- the number and sizes of pallets or containers

- additional value-add services e.g. customer-defined packaging and labelling

- physical handling requirements, e.g. hazardous or fragile items

After picking, items will usually be moved (possibly via a packing area) to an outbound marshalling area where they will be assembled with other orders destined for the same route or transporter. Picking ahead rather than picking when the orders are needed for despatch has disadvantages. The outbound area can become congested with orders that are not yet needed for despatch, while more urgent orders need to be processed.

A WMS helps streamline the allocation of resources especially when value-added processes such as labelling are required. Operations are enhanced using mobile communications to confirm instructions and information and verify outbound shipments.

To define the space required for inbound / outbound areas in a manual warehouse handling palletised goods, estimate the likely dwell time for pallets in those areas and multiply by the hourly throughput. Remember to consider seasonality and peaks within the day. Draw the resulting pallets on the layout, allowing sufficient space to manoeuvre handling equipment around them. Inefficiencies caused by lack of space on inbound and outbound docks have negative effects that ripple down to other warehouse operations.

Neglected areas

- Equipment storage and maintenance

Materials handling equipment (MHE) takes up space when not in use and provision needs to be made to store it, maintain it and charge batteries. Depending on special requirements, spare parts and consumables, there may be decisions to be made about ventilation, power sources and the storage of fuels.

- Walkways and aisles

Walkways must meet safety regulations, be clearly marked, and be separate from MHE movements. Considerations include navigating around fixtures and immovable pillars which can limit aisle widths.

- Power Plant and control rooms

Rooms must be allocated for power plants, computer servers and monitors, heating, cooling and sprinkler equipment. Each has its own safety and health requirements, Hazardous materials such as fuels and gas need additional facilities such as secure cages.

In some facilities, special secure areas must be set aside for high value items, bonded goods and items requiring quarantine. Employee welfare is a concern so adequate space should be allocated for rest areas and ablution facilities.

Final tip: Aim to keep 10% of available space in the DC open for re-packing, damaged goods for return and unplanned emergency storage.

Based on each business’ requirements, SCCG can tailor the design and layout of a Distribution Centre, having decided the inbound and outbound areas, as well as the equipment storage and maintenance, walkways and aisles, and Power Plant and control rooms.